Call to action

Food Safety Experts

Supplier of expertise, process equipment, chemistry and hygiene solutions to the global food industry.

Transporter

Aquatiq Food Safety Concept

Chemistry

Specialized chemistry for food, transport and heavy duty industry.

Training & Audits

We assist the food industry in preventing and minimizing risk related to food safety.

Analysis

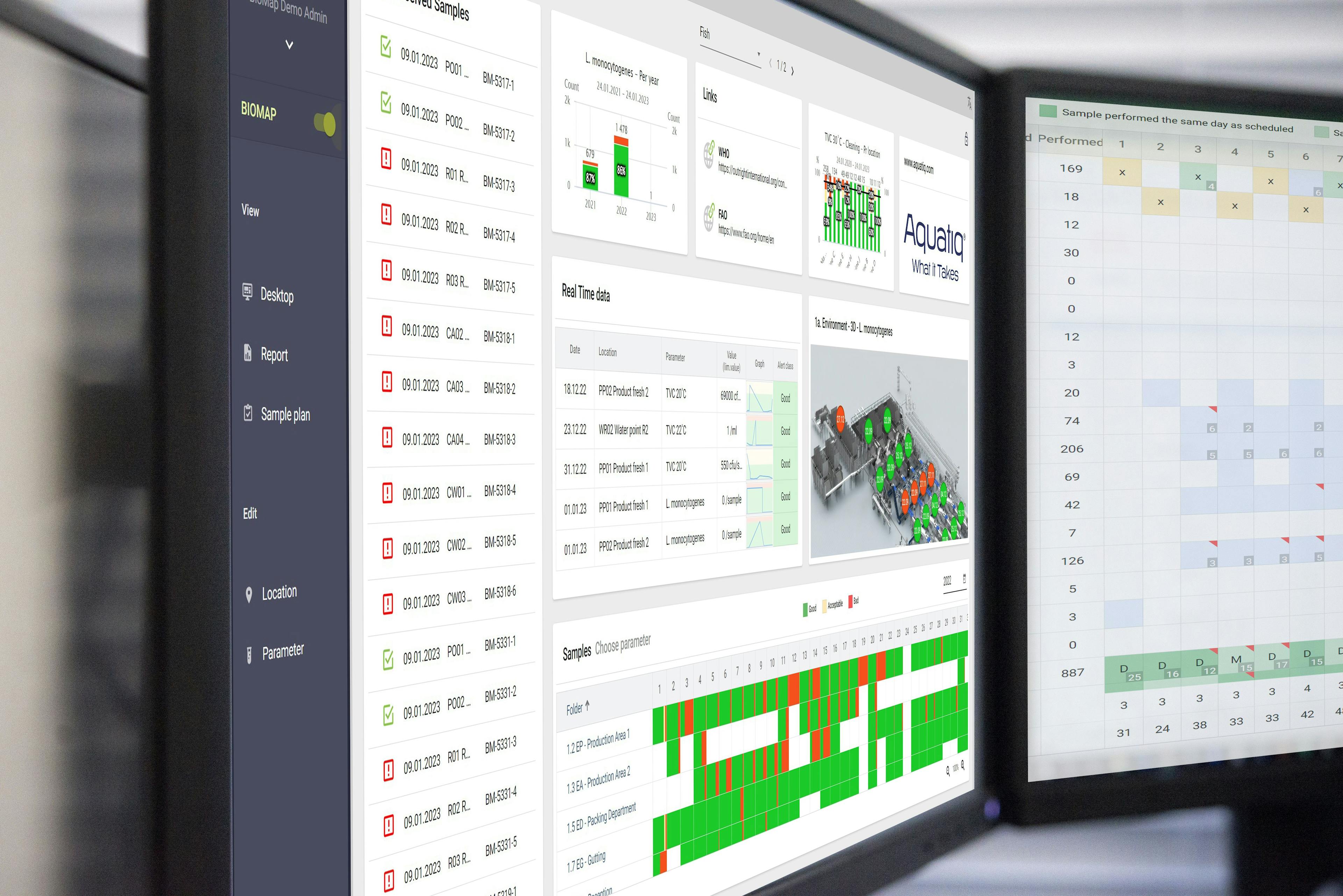

We assist in analyzing, validating and improving the company’s food safety competence. We also deliver a specialized software for monitoring analytical results in the food industry.

Cleaning Systems

Professional cleaning systems for the food industry.

Text and image section

Aquatiq Food Safety Concept covers all parts of the food production value chain and our methodology is always the same: We analyze the situation, choose the right equipment and chemicals and provide training according to the highest standards. And be assured – we will do what it takes to ensure food safety for your company.

Search box

Didn’t find what you were looking for?

Content block

Some of our valued customers

Quotes

Aquatiq is all about finding the solutions that are best for the customer

Customer

Cleaning system and chemistry

Call to action

stay updated

Follow us on LinkedIn to keep up with our latest moves and developments.