Process Equipment

Services

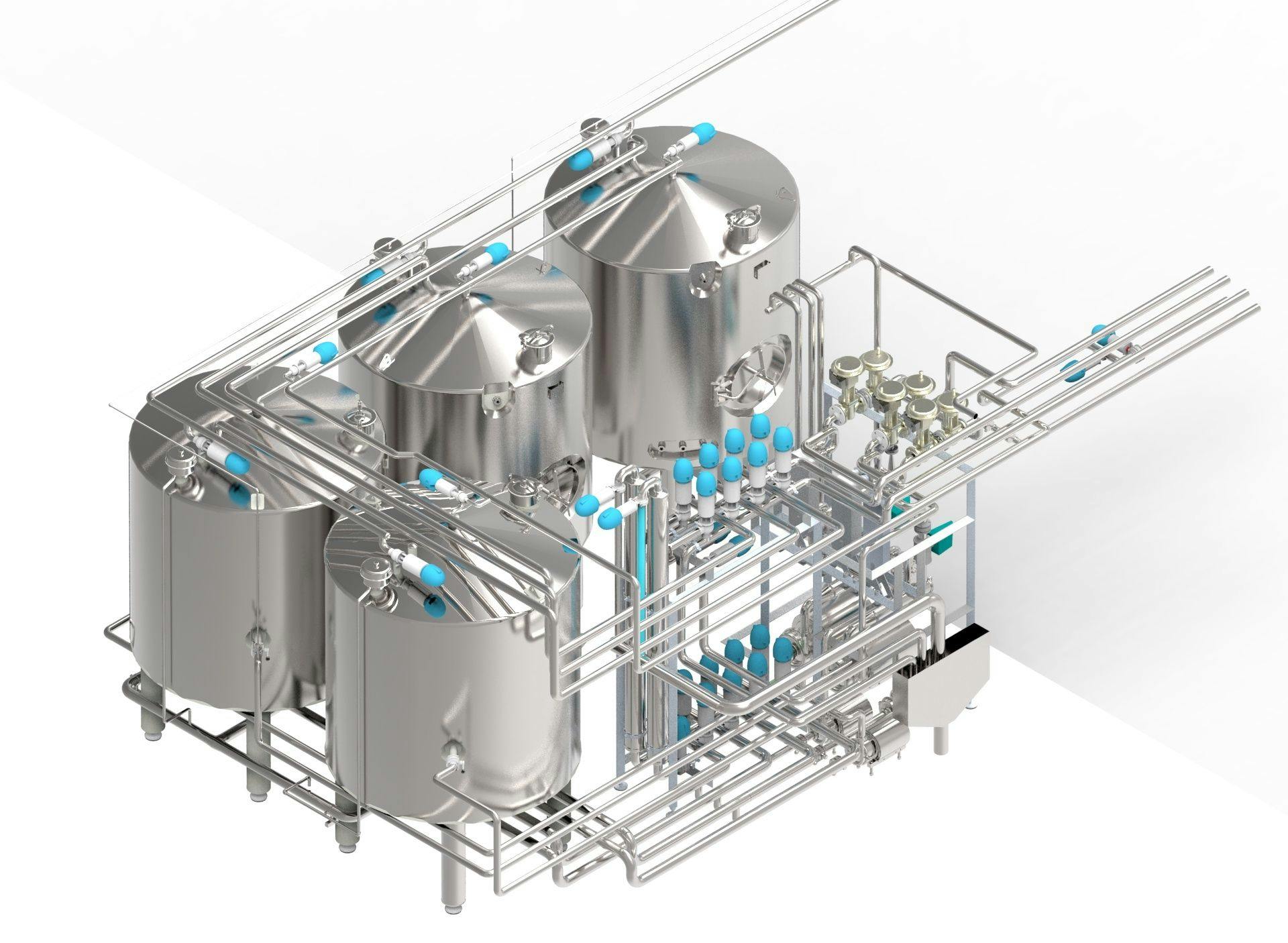

Top quality equipment and experienced installers and project managers to ensure the best result - We design and manufacture hygienic process equipment for most industries and applications

Construction

Aquatiq builds parts based on our 3D design, thereby ensuring the right quality, saving production downtime during implementation at your facility and keeping costs under control. Only certified welders are used.

Installation of prefabricated parts in an existing production environment is done by the same welders who built the plant parts in the workshop. This production method puts the focus on final quality and functionality of the plant at the forefront.

Commissioning and testing

Aquatiq carefully checks that our delivery is in order and that you have everything in place to start using the installation. The final touch and exam for the project includes performing a dry test (IO Test), wet test, CIP cleaning and finally 'Test-on-product' to ensure safe and reliable functionality.

After delivery, we are always at your service, and available to help you with your food safety.

Competence

- Safe food production

- Reliable automation

- Quality control

- Quality materials

- Experienced Automation Engineers

- Certified welders

- Controlled environment in workshop

- HSE

- S88 and S955 Functional description

Contact us

For general enquiries